Mechanical smoke extraction for even greater safety in case of fire

Fresh air + and fully-fledged technology

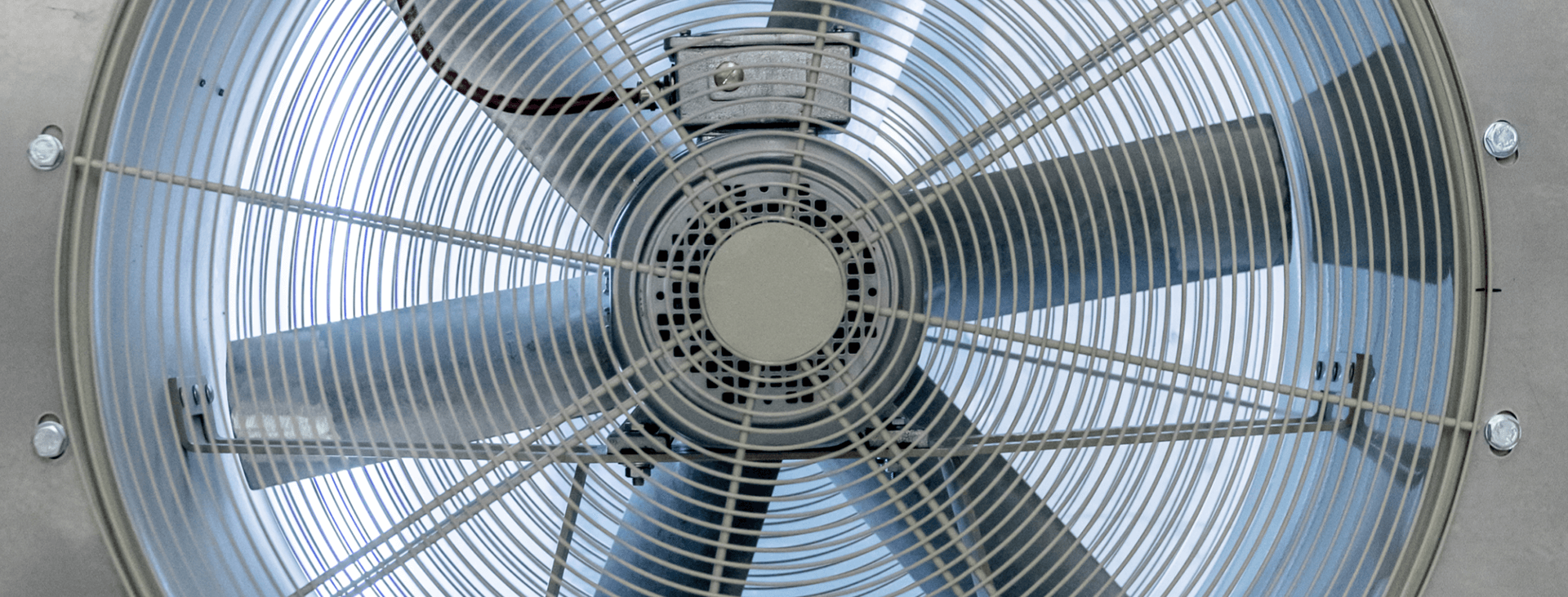

The thermal properties of flue gases and fresh air are not always sufficient to ensure safe, reliable smoke extraction from a building. There is the risk of suffocation or smoke inhalation. This issue can be addressed by using fans and smoke extraction ducts. When the function of a smoke and heat exhaust system (SHEV) is achieved with these motor-driven fans, this is defined as mechanical smoke extraction (MSE).

-

Especially fast and effective smoke extraction from buildings or underground car parks

-

Intake and exhaust air paths are opened to prevent negative pressure

-

Supply air openings near the ground prevent smoke turbulence

-

Balance between outgoing smoke and incoming fresh air

-

With D+H solutions the flow velocity of fresh air corresponds to standard specifications

Property-specific design according to use

D+H helps you plan the ideal smoke and heat exhaust system for your building – guaranteed.

The use of a mechanical smoke and heat exhaust system is recommended in particular in multi-storey buildings, interior facilities and underground car parks. Systems for mechanical smoke and heat exhaust ventilation also provide protection in shopping centres, large-scale industrial buildings, logistics centres, power plants and heating facilities.

They increase the likelihood of rescuing people who are still in the building. MSE makes firefighting operations in the building easier for the firefighters and helps protect property as well as prevent operating failures. In daily use, MSE provides general ventilation and extraction and reliably vents the building after a gas leak, such as of CO, NO2 or LPG.

What components make up an MSE system?

Versatile solutions using a wide variety of components are where the intelligent solutions from D+H deliver their full performance.

Mechanical smoke and heat exhaust systems are usually customised for a property. In other words, they are planned and then manufactured based on the application. Such a system typically consists of smoke extraction fans, automatic intake air openings, smoke extraction flaps, fire dampers, fire detectors and a control panel such as the CPS-M1-MSE from D+H.

The individual components of the system are combined into one complete system, installed and calibrated. After that, the control panel guarantees fully automated and coordinated operation of the system. In case of fire, the system goes into operation automatically as soon as smoke is detected. The system can also be triggered manually at any time.

Overview of the products

These D+H products can be used to control and monitor mechanical smoke extraction systems

One controller, many possible applications

Our CPS-M1-MSE control panel is the perfect component for simple through to highly complex solutions.

The CPS-M1-MSE controller is perfectly suited to a wide range of applications. It is a control panel for controlling systems designed to prevent the spread of smoke, heat and fire – and it can be expanded to meet individual requirements. The CPS-M1-MSE controls and monitors all components and regulates the power supply for the entire system. In everyday use, it is also suitable for controlling ventilation systems in buildings. Above all, however, the CPS-M1-MSE demonstrates its special capability in complex systems such as a mechanical smoke and heat exhaust system. The programming and structure of the CPS-M1-MSE are based on fire scenarios or on relevant directives for the design of ventilation systems.

-

Modular configuration of controller according to individual requirements

-

Additional assemblies can be retrofitted at any time

-

Freely programmable with the user-friendly D+H SCS software

-

Not dependent on the software and programmers of other PLC manufacturers

-

Supports Modbus RTU-based bus communication ACB

-

Additional cable is not required for end position messages of the ACB drives

-

Very little wiring is required, which significantly reduces the overall costs of the system

-

In the event of a power cut the system continues to operate smoothly due to the emergency power supply

-

Low energy requirements for the controller in emergency operation

Aplication examples

Mechanical smoke extraction solutions by D+H

No. 1 Old Trafford, Manchester

DH UK, the British subsidiary of D+H, implemented a solution for mechanical smoke extraction. D+H supplied not only the window drives and controllers, but also the fans and smoke extraction flaps for the extraction shafts. The scope of the project includes 2 large CPS-M1-MSE controllers, NSHEV skylights for ventilation of the stairwells, smoke extraction flaps and heat-resistant extractor fans.

Davos ice stadium

Savings in electricity consumption and a plus for well-being: Mechanical smoke extraction and natural ventilation in combination - When it comes to new buildings, D+H experts always plan the use of intake air openings for mechanical smoke extraction. And in the case of an existing building, a solution is sought to integrate existing ventilation windows into any new MSE system to be installed. This way, costs for additional intake air openings can be saved.

Lindholmen Technical Gymnasium

This extraordinary system combines 230 V window drives and 24 V window drives for natural ventilation with motor-operated fans of a powered smoke pressure system (SPS). In case of fire, an SPS uses overpressure to push the smoke out of the building through windows that have already been opened. This means that, in the event of a fire alarm, the system reacts first by opening all the windows. Next, the fans installed in the first floor blow fresh air into the building.