Innovative solutions for lift shaft smoke extraction with BlueKit.

Reduced energy costs + increased safety

BlueKit systems permanently reduce building energy costs and maximise safety at the same time. The idea behind this is both simple and ingenious: permanent openings in the lift shaft remain closed and open only in case of fire. This decreases heating costs. If the shaft openings are open continuously, as is the case in conventional configurations, heating energy escapes in an uncontrolled manner due to the chimney effect in the shaft. Sealing the top of the shaft also increases comfort in the building by eliminating the unpleasant draught effect on the inside. The BlueKit system is one of the most advanced shaft smoke extraction solutions in the world.

-

Potential for reducing the heating energy costs for the entire building by up to 7 %

-

Closing of permanent openings at the top of the shaft

-

Reliable smoke extraction in case of fire

-

System pays for itself after only a few years

-

Increases living and working comfort by reducing the draught effect

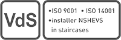

With and without BlueKit: a comparison

A great deal of valuable heat energy escapes through the permanent opening in the lift shaft. This is not only harmful to the environment, but also takes its toll on the wallet.

The BlueKit sealing element prevents heat energy escaping unnecessarily. This means that several thousand euros can be saved annually and emissions reduced. The element opens in case of fire to allow smoke to escape.

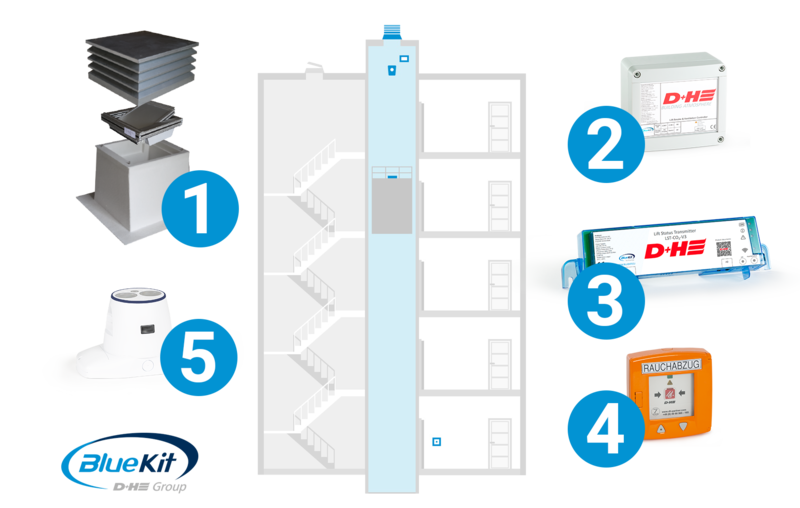

An efficient system consisting of only a few components

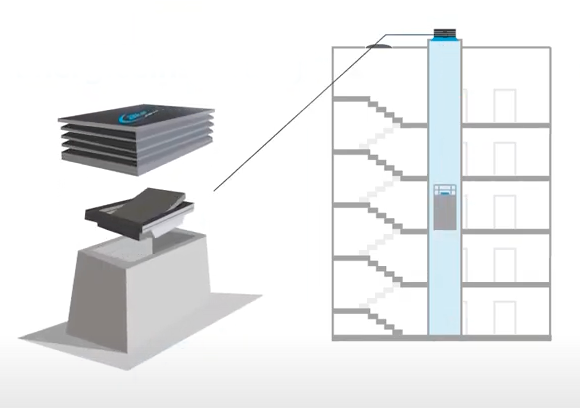

1 Ventilation Element

Stems energy losses due to sealing of the opening in the lift shaft. Ventilates and removes smoke if required.

2 Controller

Receives and forwards the trigger signal for opening the ventilation element.

3 Lift-Status-Transmitter

Monitors air quality in terms of CO2 and humidity directly at the lift car. Additional monitoring of movement or malfunctions of the lift. A ventilation signal is sent to the central unit if required.

4 Smoke Vent Button

Manual triggering of a ventilation or smoke extraction command and display of the system status.

5 Smoke Detector

Provides smoke detection throughout the entire shaft height and forwards the signal to the central unit or radio and connection unit.