Safety through smoke and heat exhaust ventilation

Saving lives + Protecting property

A person can go days without eating or drinking, but only seconds without sufficient air. Therefore, the greatest risk for people when a building is on fire is the smoke and poisonous flue gas. In case of fire, an efficient smoke and heat exhaust ventilation (SHEV) system reliably removes heat, smoke and toxic gases. This keeps escape and emergency routes clear of smoke. Firefighters and emergency workers can reach the source of the fire efficiently and evacuate people quickly. This saves lives in emergencies. Additionally, building damage is reduced significantly and property within the low-smoke layer remains largely unaffected by smoke and soot.

-

Smoke levels in escape routes are kept low: People can exit the building more quickly in an emergency

-

Hot smoke gases are allowed to escape, reducing building damage

-

Smoke extraction is triggered in seconds, before firefighters arrive

-

Quick and easy maintenance

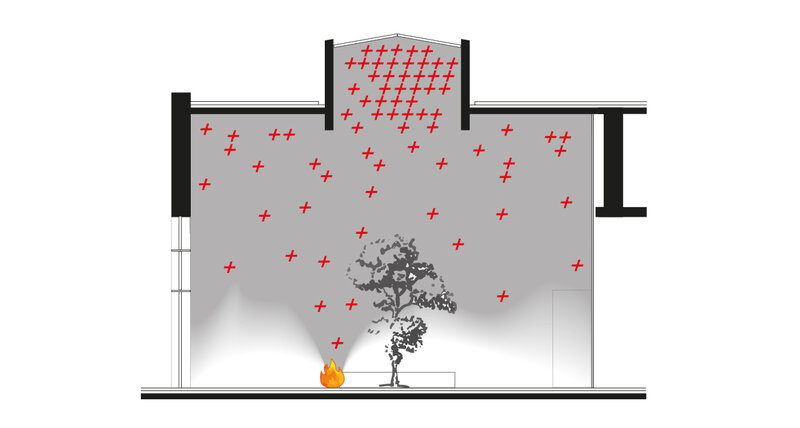

How smoke and heat exhaust ventilation works

If a build-up of smoke and heat is detected by the sensors in a building, or a smoke vent button is manually triggered, intelligent smoke extraction solutions from D+H open windows and skylights immediately in the upper wall or ceiling area. At the same time, other windows are closed to prevent smoke from reaching the areas not affected by the fire. Supply air windows in the façade admit fresh air.

As one of the first companies to use the motorised smoke vent and the first manufacturer of a certified smoke vent, we have extensive experience on the market. From stairwell smoke extraction to complex SHEV requirements for large buildings: D+H always provides a cost-effective, customised and safe system solution. Modular and digital.

With and without smoke extraction: a comparison

Intake air and exhaust air openings can be used to remove smoke and heat. Smoke is diverted to a stable smoke stratum above the area occupied by people.

Toxic fire smoke and extreme heat accumulate in the building. This endangers lives, hampers rescue efforts and causes the destruction of property.

Reliable product components for individual requirements

Our solution for complex smoke extraction situations

The digital smoke extraction controller with drives that communicate with the controller.

Maximum safety depends on precise communication. Our digital SHEV control panel is the first to provide bidirectional communication. This means that the control panel not only sends its commands to the groups, but can also respond to the drives. The result is an intelligent system in which all components communicate with each other and exchange information. This allows the new control panel to ensure maximum safety with precise communication.

An external interface can be used to control any component of the system from anywhere in the world. This is really quite smart and, thanks to the free cascadability of the system, it can also be used in any building. Due to the modular structure, CPS-M is the optimal system solution for implementing a sustainable and cost-effective smoke extraction concept for any requirement.

-

Intelligent Advanced Communication Bus (ACB) function between controller and drives

-

Networking of multiple SHEV control panels using AdComNet (ACN)

-

Software-assisted configuration of ventilation and fire compartments

-

Optimum monitoring of the connected drives and simple error diagnostics

-

Diagnostics, configuration and control directly from the control panel or remotely with remote maintenance gateway

-

Integration in existing building automation infrastructure via Modbus

-

Trade-independent connection to existing external drives

-

Plug-and-play module technology allows modules to be easily added or removed

-

Motorised 24 V and 230 V electric drives can be controlled and supplied via the CPS-M

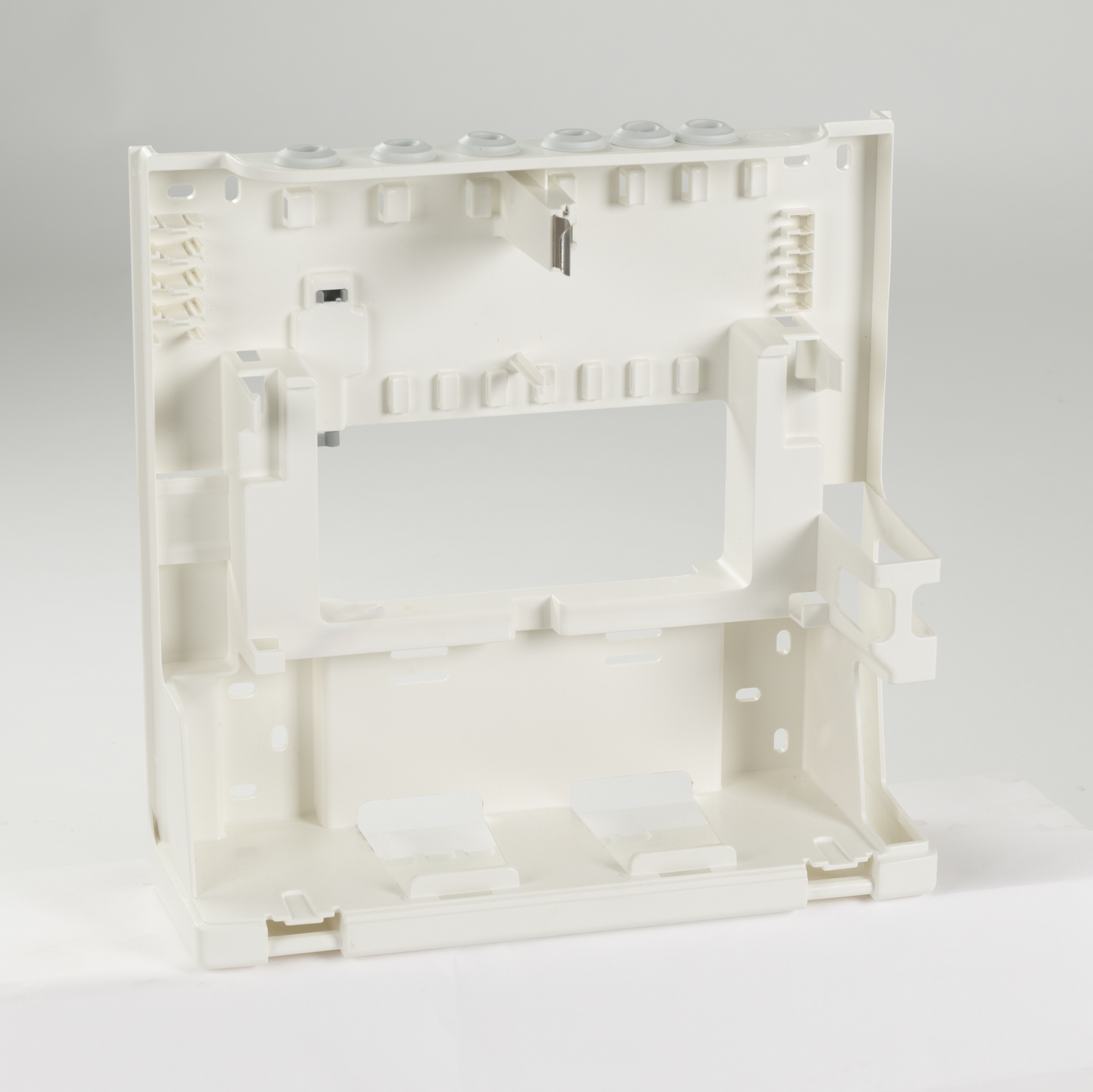

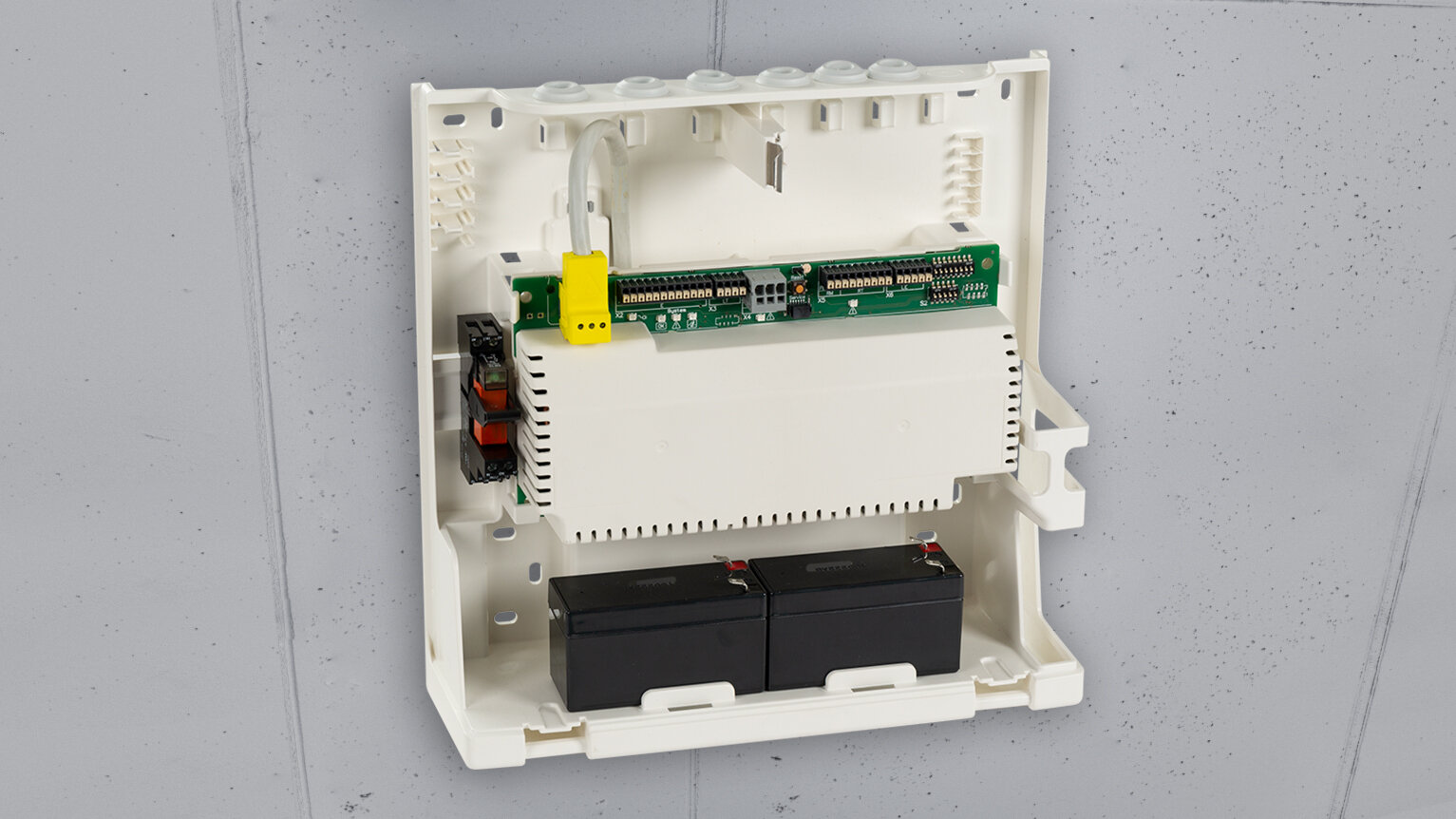

The control panel for small smoke extraction projects

Smart design and easy to install: the CPS-B smoke vent control panel from D+H offers more than just smoke extraction

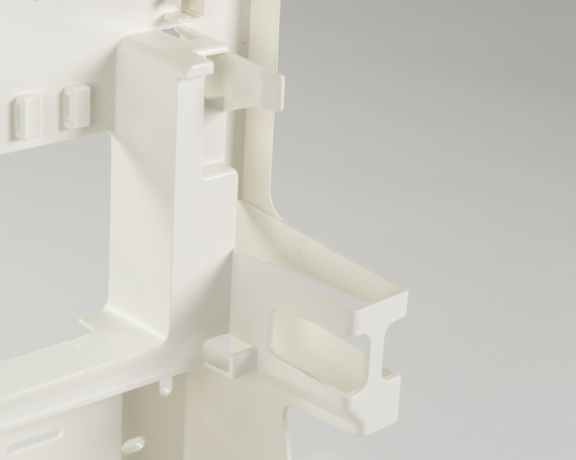

For many building projects, the tendering process for the electrical work also includes the installation of a smoke and heat exhaust system, for example in the stairwell. To control these mostly smaller systems, we recommend using the latest SHEV control panel by D+H, the CPS-B. The CPS-B significantly reduces the amount of installation work required, especially in wiring the system. This is ensured by the multifunctional, ingeniously designed housing of this compact control panel.

The housing is also designed to make the unit easy to service. The D+H development team drew on the combined practical knowledge of its own installers and customers from the very beginning. The CPS-B series control panel is VdS certified in accordance with ISO 21927-9 and fulfils the building authority requirements in accordance with DIN 18232-9.

View product

Individual solution for maximum requirements

Application for Puławy Sports Centre

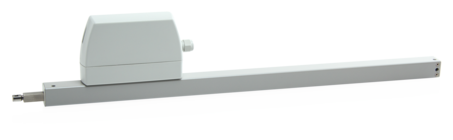

The Puławy sports centre required an exceptional smoke extraction solution for its large roof. Given the large playing area and general nature of the spaces, it was necessary to use flaps that are not only part of the smoke extraction system, but also components of the natural ventilation system. 40 oversized double-leaf top-hung windows were therefore used, each measuring 2 x 3 metres, equipped with DXD Series rack and pinion drives, and two single-leaf top-hung windows, each measuring 1.4 x 1.7 metres, also operated with DXD 300/800-BSY+HS Series drives.

In the event of a fire, the flaps installed in the Puławy sports centre open automatically, allowing toxic fumes produced by the fire to escape. All elements meet the highest quality standards: the flaps have been certified by the Polish certification department of the Deutsches Institut für Bautechnik (DIBt) for the reliability of their functional characteristics and the DXD rack and pinion drives have been issued with a certificate of approval from the Polish Scientific and Research Centre for Fire Protection (CNBOP).

More power + Less cost

230 V system for sophisticated architectural projects

With an integrated 230 V smoke vent from D+H, even the most demanding architecture projects can be implemented cost-effectively. Without any compromises in safety, security or functionality. With D+H, you have the world's first 230 V complete system with EN 12101-10 approval at your disposal. Your advantage: even with high drive power, lower cable lengths and cable cross-sections can be used, saving money and effort. This enables the cable ducts to be more slender more due to the narrower cable cross-sections, making designs with exceptional aesthetic appeal possible. The system is particularly suited for complex buildings with heavy windows which require powerful drives. Typical examples include glazed atria, industrial buildings, train stations, airports and other multi-purpose halls.

-

One-of-a-kind system with consistent 230 V AC power supply from the controller to the drives

-

More performance, less wiring: ideal for long wiring paths and applications involving particularly heavy loads

-

Cable cross-section is reduced by a factor of 100

-

VdS approval in accordance with the German VdS guidelines VdS 2581 and VdS 2593

-

Certificate of constancy of performance in accordance with EN 12101-10

Integrated 230 V smoke vent at HafenCity University Hamburg: The sophisticated glass structure at the new university for the built environment and metropolitan development at the Hamburg HafenCity would not have been possible without the 230 V smoke extraction solution from D+H. A SHEV system was developed with a 230 V emergency power supply system.

Five important questions about 230 V SHEV solutions

The key point is the cabling: for a 24 V system, the longer the building, the larger the cable cross-sections must be. This doesn't make a difference if the length is 2 m, but when cables reach lengths of 20 to 30 m, the cross-sections increase dramatically. A cable that is 100 m long, for example, can have a cross-section of over 16 mm². In larger buildings, the weight of the cables can also become a structural issue. The enormous advantage of a 230 V system is that the cross-section can be drastically reduced. The normal installation cable can be used – in almost any length.

The cost savings are enormous: with a 230 V solution, we can provide power to distant flaps and drives with significantly less expensive cables and lower weight. This makes the entire system more cost-effective. For smaller structures, such as a stairwell, a 24 V system is ideal. However, once we start talking about multiple storeys or an industrial building, for example, where the cable routes are longer due to the inherent nature of the building, the 230 V solution is clearly more cost-effective.

Of course, we can provide some sample calculations. If we assume a cable route of 100 m for a complete SHEV system in a building, the total savings for control panels and cables would be several thousand euros. The difference becomes greater the longer the cable routes are. But the cost factor is not the only consideration. The visual advantages can also be a deciding factor. Large cable trays for a 24 V emergency power supply are sometimes difficult to reconcile with architects' ideas. In the 230 V solution, cable trays become much smaller and less obtrusive. Planners very often have problems with overloaded cable trays. One solution would be to have cabling with significantly smaller cross-sections.

The SHEV control panel can be used to control and supply both 230 V and 24 V components. Whereas our drives are all designed for 24 V or 230 V, the weather sensors, for example, are supplied with 24 V. Using the 24 V plug-in unit in the SHEV control panel, we are able to supply the power for the weather control panel and, at the same time, supply the sun shading drive using the 230 V plug-in unit, for example. This interaction is very important for large buildings.

The level of awareness isn't where it should be yet. We would like the communication among various specialist planners to be improved through comprehensive coordination. This would make the advantages clear to planners in different areas as well. Electrical planners could benefit from lower cable costs, structural engineers could benefit from lower cable cross-sections and architects can put their design ideas into practice. In our experience with the previously mentioned example structures, you can see very clearly that everyone benefits from increased collaboration between those involved.

Economical, with certainty

Highest performance at low cost: our 230 V system

The 230 V SHEV system is the only system in the world with a consistent 230 V power supply from the controller to the drives — designed for use in complex buildings with long wiring routes and various heavy-duty applications in the roof area. It offers the perfect combination of maximum performance and minimal cabling, with space for various plug-in units for smoke vent and ventilation functions. This makes the system especially simple to install and easy to retrofit.

Helper in need: the 230 V emergency power supply NSV 401. In addition to VdS approval, it also boasts a certified constancy of performance in accordance with EN 12101-10. The 230 V emergency power supply also has inverters with high-quality sine-output voltage, various status displays and a battery-powered impedance monitor. Faulty batteries can be changed easily. This makes the 230 V emergency power supply both reliable and cost-efficient.

View product