CREATIVE + Close

The D+H company album: A corporate success story in pictures

From development garage to innovation driver

Over the course of D+H's history going back almost 50 years, the company has brought countless innovations to the market. Choosing the most successful is not an easy task. The three listed here helped give us a big push to the top.

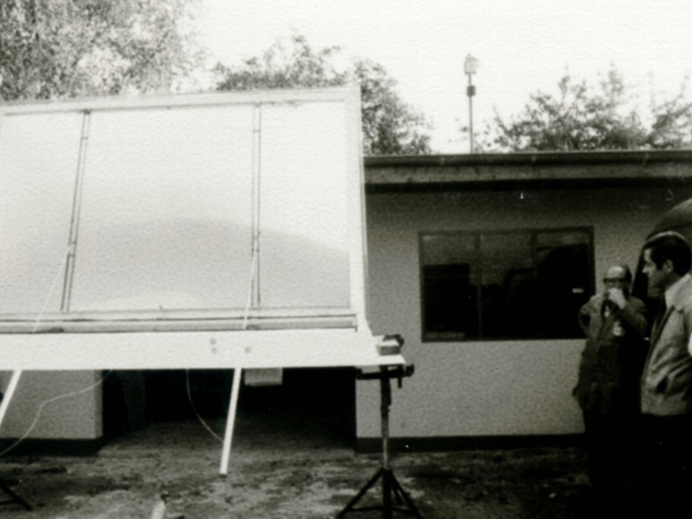

The first electric SHEV system on a sample board.

The sample board (circa 1972) is the first complete smoke vent system from D+H. The letters EHP stand for Electric-Pneumatic-Hydraulic and were a product brand and previously part of the company's name. In addition to a smoke detector, button and drive for the fittings (below on the left), the system also included the first D+H ZA 500 rack and pinion drive, which happened to be powered by a repurposed windscreen wiper motor.

The first chain drive with undisputed performance.

The KA 30 was the first chain drive that D+H developed and manufactured itself. Its performance data with a stroke of up to 800 mm and 300 N of force gave it a unique selling point on the market in the mid-1990s. Its invention with a solid side bow chain made it possible to install a window drive immediately adjacent and parallel to the sash, meaning it did not protrude into the room as had been the case with rack and pinion drives up to that point. The KA is the device that does it all among D+H chain drives and remains a timeless classic.

The smoke vent button that became the global standard.

The orange-coloured smoke vent button (photo from year 2000) has become an icon in the industry and a synonym associated with D+H. It can be found in countless stairwells and hallways all over the world. Since the company's founding, more than a million units have been sold. It and its successors remain D+H's top sellers. An interesting detail: The small graphic on the left next to the button was created by Helmut Kern. Just another example of how D+H's inventions become the standard over time.

Long road to success

Approximately five decades of corporate history at a glance.

1972:

The first electric 12 volt SHEV system with emergency supply

1973:

The first 24 volt rack and pinion drive with a large stroke and short runtime

1973:

The first electronic safety cut-off with current measurement

1973:

The first 24 volt modular control panel with emergency supply and monitoring for all lines

1975:

The initial use of LEDs for safety messages

1976:

The first use of wind and rain sensors in combination with SHEV ventilation systems

1977:

The first large control panel with multiple groups and lines

1979:

The first control panel with slots for plug-in units

1980:

The first trigger button in a DIN-compliant fire button housing

1981:

The first type testing for electric SHEV systems by the TÜV Berlin testing association

1986:

Systematic training and testing of set-up technicians for the electric SHEV system from D+H

1988:

The first servo control for convenient climate control for ventilation SHEV drives

1991:

The first fire testing of SHEV drives in accordance with DIN by TÜV in the fire testing facility

1994:

The first manufacturer for electric SHEV systems with quality assurance in accordance with ISO 9001 certified by VdS

1994:

The first electric drive for SHEV from MPA-NRW successfully tested in a DIN fire test

1995:

The first participant in the DIN standardisation work for electric natural SHEV

1995:

The first chain drive for SHEV with precision chain and end stabilisation for large strokes

1995:

The first twin chain drive for optimal force application, cut-off reliability and design

1998:

Innovative side bow chain with elastic stabilisation and bending limit

1998:

Compact door/side hung vent drive based on a chain with rigid backing

2000:

The first manufacturer of electric SHEV systems with successful testing of all components for electric SHEV drives by VdS

2001:

Synchronisation integrated into the drive with intelligent load distribution and safety cut-off

2002:

The narrowest lock drive able to be integrated into a profile

2003:

The first chain drive for directly connecting to closing-edge monitoring

2004:

New skylight opening system with optimised kinematics and dual rack and pinion drive for maximum efficiency

2006:

The first 230 volt SHEV system with approved cable monitoring

2006 :

Generation change within the family-owned company

2007:

Drive parameter configuration over Bluetooth with PDA/smartphone and Powerline programming

2010:

First secure bus communication system AdComNet for building automation in a case of fire

2011:

Certification of the D+H environmental management according to DIBN ISO 14001

2011:

First solar-powered window drive VCD-S with integrated solar panel

2012:

Expansion of the Headquarters with an investment of Euro 7 million

2012:

Winner of the "Grand Prize for medium-sized Companies Award"

2013:

Development of the CDP Series as the most powerful chain drive series

2015:

Winner of the "German Education Award"

2016:

The new digital smoke ventilation control panel CPS-M, biggest development project, comes onto the market

2017:

D+H wins the German Brand Award thanks to the new brand promise "BUILDING ATMOSPHERE"

2018:

The company's 50th anniversary is celebrated in the hall of the Hamburg Chamber of Commerce and with a fair on the company grounds

2019:

Merger of D+H Mechatronic AG with Dingfelder + Hadler AG and integration of the BlueKit Factory GmbH

2020:

Expansion of the American partner network with new partners in Colombia and California

2021:

Entry into the business area of mechanical smoke extraction (MSE)

2022:

Foundation of the French subsidiary D+H France S.A.S

2023:

Expansion of the Board with the addition of the two long-standing management members Maik Schmees and Mirko Matenia

Driven by the lasting values of our fathers; we are shaping the future of D+H on international markets with our passion and sound judgement. We are trying to turn the complex challenges of our digitised world and simultaneous demographic change into an opportunity.

Dirk Dingfelder & Christoph Kern